Oct . 02, 2024 11:26 Back to list

about diaphragm pressure gauge quotes

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

Diaphragm pressure gauges are essential instruments used to measure pressure in various industrial applications. Their design and functionality make them particularly useful in scenarios where accuracy and reliability are paramount. This article explores the key features, applications, and advantages of diaphragm pressure gauges, providing insights into why they are a preferred choice for many professionals.

What is a Diaphragm Pressure Gauge?

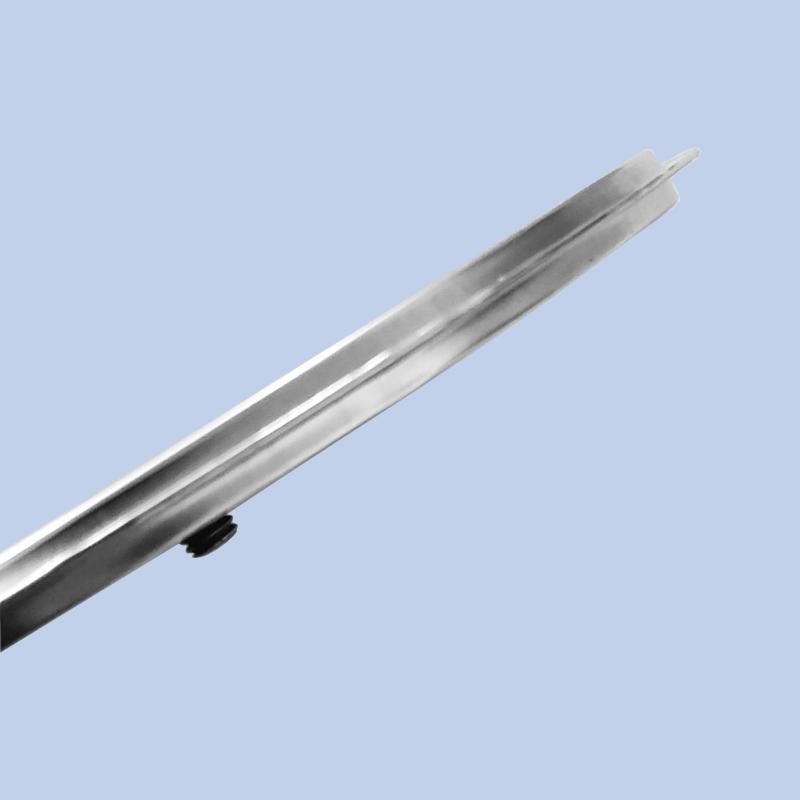

A diaphragm pressure gauge operates based on the principle of a flexible diaphragm that responds to pressure changes. The diaphragm is typically made of materials such as stainless steel, which provides excellent corrosion resistance and durability. When pressure is applied, the diaphragm deflects, and this movement is converted into a measurable reading. This design allows diaphragm gauges to handle both gaseous and liquid media, making them versatile tools in the field.

Key Features

1. High Accuracy Diaphragm pressure gauges are known for their precision. The design allows for minimal friction and wear, ensuring that the readings remain consistent over time.

2. Corrosion Resistance The materials used in constructing diaphragm gauges make them suitable for harsh environments. They can withstand exposure to various chemicals, allowing for accurate measurements even in challenging conditions.

3. Wide Pressure Range These gauges can measure a broad spectrum of pressure levels, from low vacuum pressures to high-pressure applications. This adaptability makes them suitable for a wide range of industries.

4. Compact Design Diaphragm pressure gauges have a relatively small footprint compared to other pressure measurement devices, making them ideal for applications with limited space.

Applications

Diaphragm pressure gauges find their applications across various sectors, including

about diaphragm pressure gauge quotes

1. Chemical Processing In chemical plants, where corrosive substances are prevalent, diaphragm gauges provide reliable measurements critical for maintaining safety and efficiency.

2. Oil and Gas The oil and gas industry relies on accurate pressure readings to ensure safe operations. Diaphragm gauges help monitor pressure in pipelines and storage tanks.

3. Food and Beverage In food production, maintaining precise pressure is vital for ensuring product quality and safety. Diaphragm gauges are often used in these processes.

4. Pharmaceuticals The pharmaceutical industry demands high standards for measurement accuracy. Diaphragm pressure gauges are employed to monitor processes, ensuring compliance with regulations.

Advantages of Diaphragm Pressure Gauges

1. Low Maintenance These gauges typically require less maintenance compared to other types, such as bourdon tube gauges. Their robust construction allows for prolonged use without frequent calibration.

2. Wide Compatibility Diaphragm gauges can be designed to handle various media, including viscous liquids, gases, and aggressive chemicals, expanding their usability across different applications.

3. Cost-Effective While the initial investment might be higher than other types of gauges, the durability and low maintenance costs of diaphragm gauges often result in a lower total cost of ownership over time.

Conclusion

In conclusion, diaphragm pressure gauges are indispensable tools in modern industrial applications. Their accuracy, durability, and adaptability make them a preferred choice for many industries, including chemical processing, oil and gas, food production, and pharmaceuticals. By understanding the benefits and capabilities of diaphragm pressure gauges, professionals can make informed decisions that enhance their operational efficiency and safety. As technology continues to evolve, we can expect further advancements in pressure measurement, solidifying the role of diaphragm gauges in a wide array of applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025