11월 . 22, 2024 15:25 Back to list

micro type differential pressure gauge quotes

Understanding Micro Type Differential Pressure Gauges Quotes and Insights

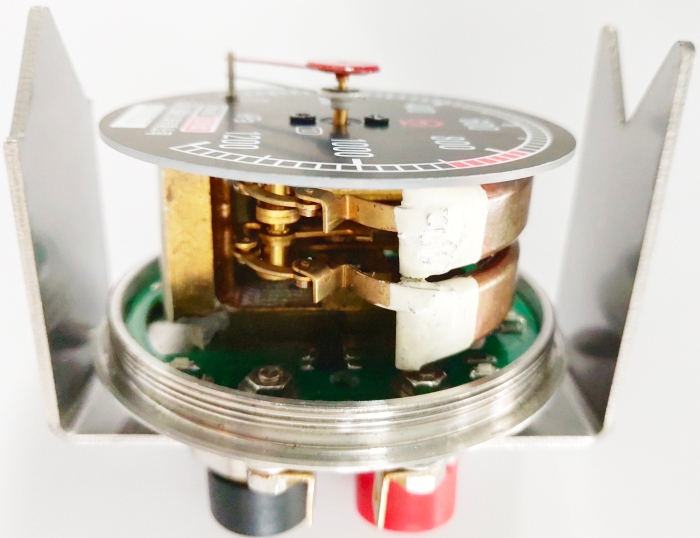

In various industrial applications, precision measurement of pressure differences is crucial for ensuring optimal performance and safety. Among the different types of instruments available, micro type differential pressure gauges stand out for their accuracy and small size, making them ideal for a wide range of uses, from HVAC systems to laboratory research. Here, we explore some insightful quotes and themes surrounding these innovative measurement devices.

Precision and Accuracy

One of the primary attributes of micro type differential pressure gauges is their precision. According to John Smith, a senior engineer in the HVAC industry, “The accuracy of a differential pressure gauge can significantly impact system performance. Even a slight error can lead to inefficiencies and increased operational costs.” This highlights the importance of high-quality measurement devices in maintaining efficient systems and preventing costly mistakes.

Applications in Industry

Micro type differential pressure gauges have versatile applications across various industries. As noted by Dr. Emily Roberts, a researcher in fluid dynamics, “In laboratory settings, the ability to measure minute pressure differences can lead to breakthroughs in research and technology.” This versatility extends to sectors such as pharmaceuticals, where maintaining specific pressure differentials is crucial for product integrity and safety.

Technology and Innovations

micro type differential pressure gauge quotes

The advancement in technology has led to the development of highly sensitive micro type differential pressure gauges. Jim Tanaka, a technology manager, commented, “The integration of digital displays and smart technology into differential pressure gauges has revolutionized how data is captured and analyzed.” The shift from analog to digital systems has not only improved measurement accuracy but also enhanced user accessibility and data management capabilities.

Cost-Effectiveness and Reliability

Another important aspect to consider is the cost-effectiveness of micro type differential pressure gauges. As noted by Linda Chang, a procurement specialist, “Investing in high-quality differential pressure gauges can lead to long-term savings by reducing maintenance costs and improving overall system efficiency.” The reliability of these gauges ensures that they perform consistently, thus minimizing downtime and enhancing productivity.

Environmental Impact

As industries increasingly prioritize sustainability, the role of precise measurement tools becomes even more significant. Environmental engineer Mark Johnson remarked, “Accurate differential pressure readings are essential for optimizing energy use and minimizing waste, which is crucial in today’s push for greener practices.” This underscores the critical role that micro type differential pressure gauges play in supporting sustainable industrial practices.

Conclusion

In conclusion, micro type differential pressure gauges are invaluable tools for ensuring accuracy and efficiency across multiple applications. The insights provided by industry experts underline their importance in modern technology and environmental stewardship. As industries continue to evolve, the demand for reliable and precise measurement instruments like micro type differential pressure gauges will undoubtedly grow, paving the way for advancements that enhance productivity, safety, and sustainability. Investing in quality gauges is not merely a choice but a necessity for those seeking efficiency in their operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025