Sep . 28, 2024 22:32 Back to list

Understanding Metal Diaphragm Pressure Gauges and Their Applications in Various Industries

Metal Diaphragm Type Pressure Gauges An Overview

Pressure measurement is a crucial aspect of various industrial processes, and one of the most reliable instruments used for this purpose is the metal diaphragm type pressure gauge. This device, known for its accuracy and robustness, plays a vital role in ensuring the safe and efficient operation of machinery, equipment, and systems across diverse applications, from oil and gas to pharmaceuticals.

Understanding Metal Diaphragm Pressure Gauges

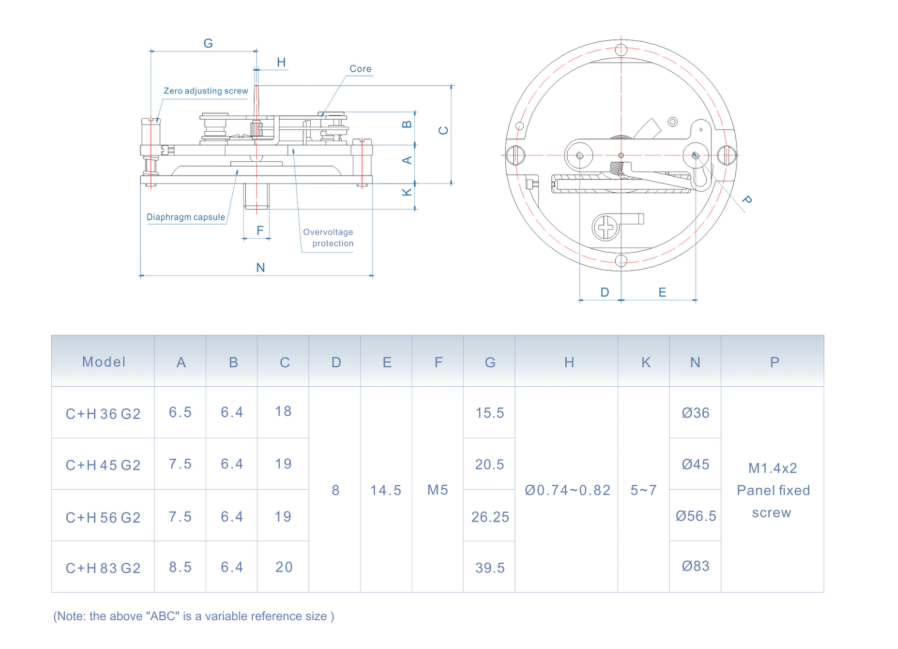

Metal diaphragm pressure gauges are designed to measure pressure by utilizing a flexible metal diaphragm. This diaphragm is typically made from materials such as stainless steel, which provides both strength and resistance to corrosion. When pressure is applied to the diaphragm, it deflects proportionally. The amount of deflection is then translated into a pressure reading using a set of mechanical linkages and a needle indicator on a calibrated dial.

The construction of these gauges allows them to withstand high pressures while providing a high level of accuracy, typically within ±1% of full scale. This precision is essential in applications where even minor pressure variations can lead to significant operational issues or safety hazards.

Applications

The versatility of metal diaphragm pressure gauges makes them suitable for a wide range of applications. One of the most common uses is in the oil and gas industry, where they monitor pressures in pipelines and tanks to prevent leaks and ensure operational efficiency. They are also extensively used in chemical plants, water treatment facilities, HVAC systems, and food and beverage industries.

In industries involving harsh environments, such as mining or petrochemicals, metal diaphragm gauges are preferred due to their ability to perform reliably under extreme conditions, including high temperatures and aggressive substances. Their robust construction reduces the risk of failure, which is critical in maintaining safety standards.

Advantages of Metal Diaphragm Pressure Gauges

metal diaphragm type pressure gauges

1. Durability The metal diaphragm's resistance to mechanical stress and corrosive elements enhances the gauge's lifespan. Unlike liquid-filled gauges, metal diaphragms are not susceptible to leakage or evaporation, ensuring consistent performance over time.

2. Wide Pressure Range Metal diaphragm gauges can measure a broad spectrum of pressures, from very low to extremely high levels, making them adaptable for various applications.

3. Compact Design The design of metal diaphragm gauges is generally more compact than other pressure measurement devices, allowing for easier installation in tight spaces.

4. Minimal Maintenance Due to their rugged construction, these gauges require minimal maintenance compared to other types of gauges that may need regular calibration or substance refills.

Considerations When Choosing a Metal Diaphragm Gauge

While metal diaphragm pressure gauges offer numerous advantages, selecting the right gauge for a specific application involves consideration of several factors

- Pressure Range Ensure the gauge is rated for the maximum and minimum pressures it will encounter. - Operating Environment Assess the chemical compatibility of the diaphragm material with the media being measured and ensure it can withstand environmental conditions such as temperature fluctuations and exposure to corrosive substances. - Mounting Options Depending on installation requirements, consider the orientation and mounting style of the gauge.

Conclusion

Metal diaphragm type pressure gauges stand out as essential tools in industrial pressure measurement, combining durability, accuracy, and versatility. Their ability to operate in challenging conditions without considerable maintenance makes them a preferred choice for many industries. Understanding their features, advantages, and appropriate applications is crucial for engineers and technicians who rely on precise pressure readings to ensure the smooth and safe operation of their systems. With ongoing advancements in technology, these gauges continue to evolve, promising even greater efficiency and reliability in the future.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025