Oct . 13, 2024 11:40 Back to list

odm capillary type differential pressure gauge

Understanding ODM Capillary Type Differential Pressure Gauges

Differential pressure gauges are essential instruments in various industrial applications, used to measure the difference in pressure between two points in a system. Among the different types of differential pressure gauges, the ODM (Optical Device Measurement) capillary type has gained significant attention due to its accuracy, reliability, and versatility.

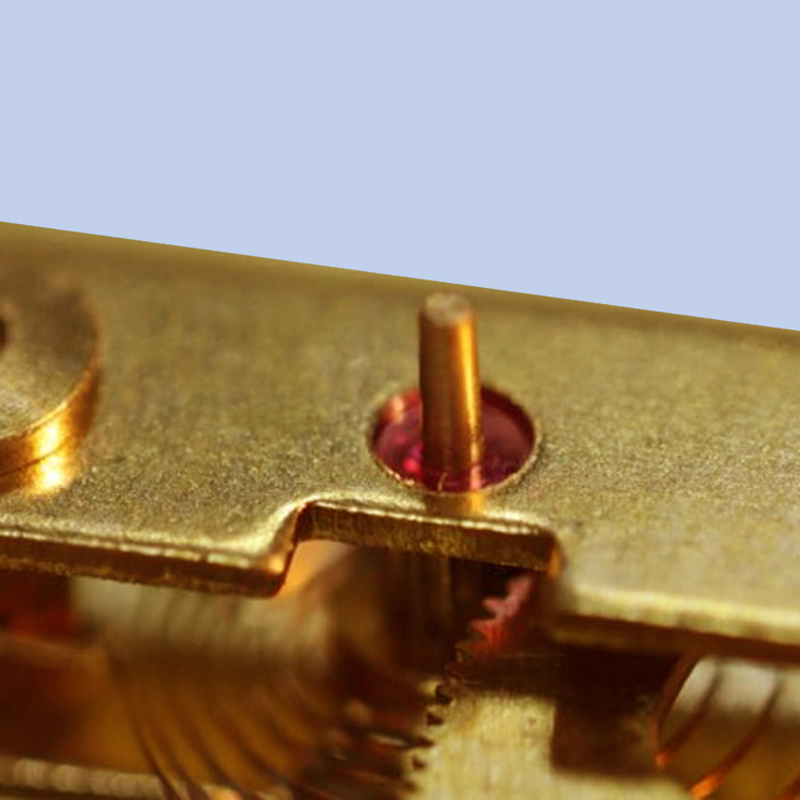

The ODM capillary type differential pressure gauge employs a capillary tube to connect the two pressure points. This design allows for the effective transmission of pressure changes to a sensing element, typically a diaphragm or Bourdon tube, which then translates these changes into a readable output. The capillary tube facilitates the isolation of harmful substances or extreme conditions from the gauge itself, enhancing its longevity and performance.

One of the primary advantages of the ODM capillary type is its excellent sensitivity to small pressure differentials

. This sensitivity is crucial in processes where minor fluctuations can have significant consequences, such as in chemical processing, pharmaceuticals, and HVAC systems. The gauge’s design minimizes the effects of temperature fluctuations, ensuring consistent and accurate readings.odm capillary type differential pressure gauge

In addition to sensitivity, the ODM gauge is renowned for its robustness. The use of high-quality materials in the construction of the capillary and sensing elements means that these gauges can withstand harsh environmental conditions, including corrosive or high-temperature environments. This durability makes them a preferred choice in industries like oil and gas, water treatment, and food processing, where reliability is paramount.

Installation and maintenance of the ODM capillary type differential pressure gauge are straightforward, making it a user-friendly option for many applications. The gauge can be installed in various orientations and requires minimal adjustment after installation. Regular maintenance involves simple checks for blockages in the capillary tube and ensuring that the gauge is correctly calibrated, which enhances its lifecycle and performance.

The versatility of the ODM capillary type differential pressure gauge cannot be overstated. They can be used in a wide range of applications, from measuring gas flow in pipelines to monitoring liquid levels in tanks. Their ability to measure both positive and negative pressure differentials makes them indispensable across many sectors.

In conclusion, the ODM capillary type differential pressure gauge stands out as a reliable and accurate tool for measuring pressure differences in various industries. With its exceptional sensitivity, robust design, and ease of use, it continues to be an integral part of modern industrial processes, ensuring optimal performance and safety. As industries evolve, the relevance of such precision instruments will only grow, underscoring their importance in maintaining efficiency and effectiveness in operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025