Dec . 18, 2024 19:39 Back to list

hydraulic differential pressure gauge manufacturers

Understanding Hydraulic Differential Pressure Gauges Key Manufacturers and Their Importance

Hydraulic differential pressure gauges are vital instruments in various industrial applications, particularly in hydraulics and fluid mechanics. These gauges measure the difference in pressure between two points in a system, providing essential data for monitoring system performance and safety. In this article, we will explore the significance of hydraulic differential pressure gauges, the features that distinguish them, and some of the leading manufacturers in the industry.

What Are Hydraulic Differential Pressure Gauges?

A hydraulic differential pressure gauge is designed to measure the pressure difference between two fluid points. Typically, these gauges consist of a sensing element that responds to pressure changes and displays the differential pressure through a dial or digital readout. They are widely used in hydraulic systems, where monitoring fluid pressure is crucial for operational efficiency and safety.

The functionality of these gauges is critical in various industries, including oil and gas, food and beverage, pharmaceuticals, and power generation. These applications require precise pressure readings to ensure that systems operate within safe and efficient parameters. For instance, in oil and gas extraction, monitoring the differential pressure between two well points can provide essential data about reservoir behavior.

Importance of Accurate Measurements

Accurate pressure readings are vital for optimizing system performance. Hydraulic differential pressure gauges help operators detect potential issues such as leaks, blockages, or worn-out components, allowing for preventive maintenance before significant failures occur. For example, a sudden increase in differential pressure may indicate a blockage in filters or pipelines, alerting operators to take immediate action.

Moreover, these gauges play a crucial role in maintaining product quality and safety standards in food and pharmaceutical industries where pressure anomalies can lead to contamination or product failure.

Features to Consider

When selecting a hydraulic differential pressure gauge, several features are essential to ensure optimal performance

1. Range The gauge must be capable of measuring the specific pressure range relevant to the application. 2. Accuracy Precision is critical in measurement. Look for gauges with high accuracy ratings. 3. Durability The design materials should withstand the operating environment, including temperature, humidity, and exposure to corrosive fluids.

hydraulic differential pressure gauge manufacturers

4. Response Time A quick response time is important for real-time monitoring, especially in dynamic systems. 5. Calibration Look for gauges that are easy to calibrate, ensuring they maintain accuracy over time.

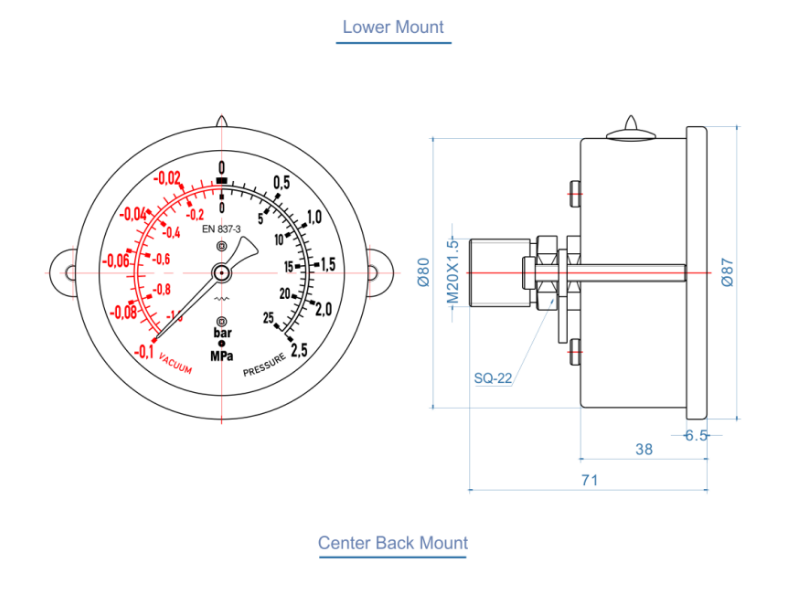

6. Mounting Options The installation flexibility can significantly affect the practicality of the gauge in various settings.

Key Manufacturers in the Industry

Several manufacturers have established themselves as leaders in the production of hydraulic differential pressure gauges. Some notable companies include

1. WIKA Instruments Known for its robust range of pressure measurement products, WIKA offers gauges that provide high accuracy and excellent reliability in harsh environments. 2. Honeywell A global leader in technology, Honeywell produces a variety of pressure measurement devices, including advanced digital differential pressure gauges.

3. Ashcroft With a reputation for durability and precision, Ashcroft’s gauges are commonly used in critical applications across various industries.

4. Emerson Their offering includes specialized pressure gauges designed for demanding applications, ensuring reliability and performance.

5. Omega Engineering Known for a wide array of engineering products, Omega’s differential pressure gauges offer innovative features and high precision.

Conclusion

Hydraulic differential pressure gauges play a crucial role in maintaining the efficiency and safety of hydraulic systems. Their ability to provide accurate pressure readings enables operators to understand system performance and address issues promptly. As industries continue to evolve, the demand for reliable and durable pressure measurement devices will remain high, emphasizing the importance of reputable manufacturers in delivering quality products. Investing in high-quality hydraulic differential pressure gauges is essential for any business looking to optimize operations and ensure safety in their processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025